Ferrite Core Inductor Software Applications

Most applications of iron powder cores are substitutions of inductors made of ferrite cores. These applications include DC/DC converter output filter inductors and power factor correction inductors.

Switching frequency 100-1000 kHz: Ferrite, Superflux, WE-PERM Switching frequency 1000 kHz: Ferrite, WE-PERM Inductor current ratings The current load for power inductors can be calculated very accurately in terms of DC current load and ripple current load (core losses) using the manufacturers’ simulation software.

In these applications you need the energy storage capability (proportional to $ B times H $; all quantities are magnitudes) of the inductor core. Ferrite cores have a high permeability so you need to introduce an air gap to reduce this permeability, thus increasing the magnetic field $H $ strength needed to magnetize the core to a flux density $ B $. This air gap has a severe disadvantage: within the air gap the relative permeability is reduced to unity and this causes the flux to exit the core and enter the winding, leading to eddy current losses in the winding. The power loss density is concentrated around the air gap, so there is the risk of a hot spot.

Iron powder cores do not need the additional air gap since it is integrated into the material and, in consequence, spread within the complete core volume. This reduces the eddy current losses in the winding and the remaining eddy current losses are distributed throughout the winding length. Furthermore, energy storage is limited by the saturation flux density. In ferrite this saturation flux density is about 400 mT and decreases with temperature. In iron powder cores saturation flux densities of more than 1 T can be utilized, depending on the material. As you mentioned Micrometals core: Micrometals, Inc. Offers an that can be used to design basic inductors including power loss calculations.

May 6, 2016 - In order to get some hands-on experience with implementing neural networks I decided I'd design a system to solve a similar problem: Automated number plate recognition (automated license plate recognition if you're in the US). My reasons for doing this are three-fold: I should be able to use the same (or. Abstract: Automatic License Plate Recognition system is a real time embedded system which automatically recognizes the license plate of vehicles. There are many applications ranging from complex security systems to common areas and from parking admission to urban traffic control. Automatic license plate recognition. In this tutorial I show how to use the Tesseract - Optical Character Recognition (OCR) in conjunction with the. Aug 2, 2017 - In this tutorial, I'll be taking you through the basics of developing a vehicle license plate recognition system using the concepts of machine learning with Python. What exactly are we trying to do? License Plate Recognition Systems use the concept of optical character recognition to read the characters on a. License plate recognition opencv. OpenALPR is an open source Automatic License Plate Recognition library written in C++ with bindings in C#, Java, Node.js, Go, and Python. The library analyzes images and video streams to identify license plates. The output is the text representation of any license plate characters.

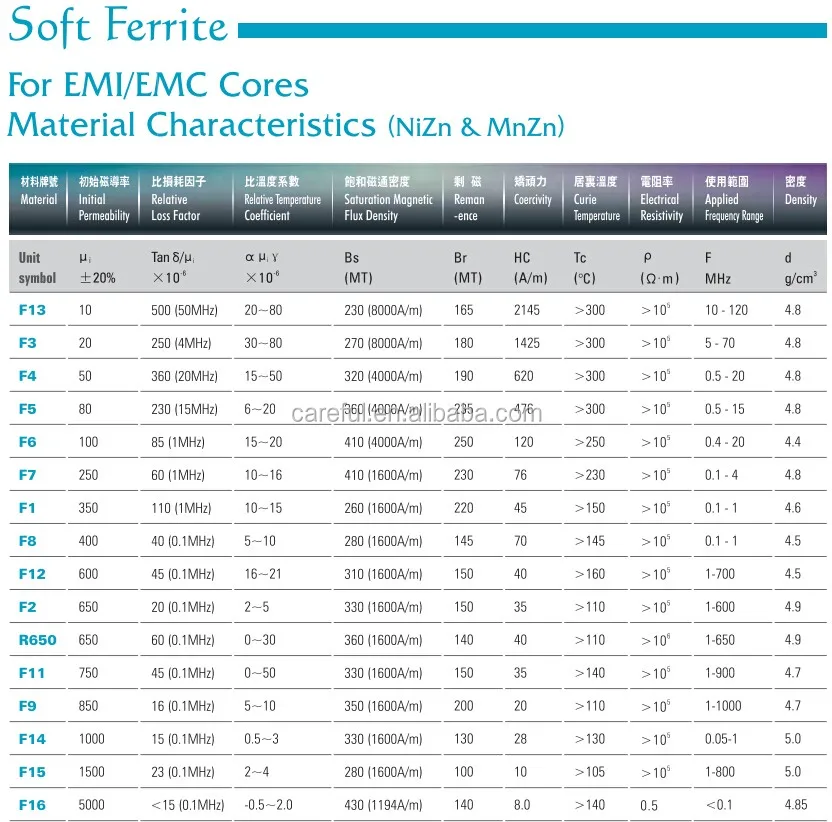

Contents. Ferrites Ferrites are ceramic compounds of the with, which are but nonconductive. Ferrites that are used in or contain oxides combined with, and/or compounds.

They have a low and are called ' soft ferrites' to distinguish them from ' hard ferrites', which have a high coercivity and are used to make. The low coercivity means the material's can easily reverse direction without dissipating much energy , while the material's high prevents in the core, another source of energy loss. The most common soft ferrites are:. Manganese-zinc ferrite ( MnZn, with the formula Mn aZn (1-a)Fe 2O 4). MnZn have higher and than NiZn.

Nickel-zinc ferrite ( NiZn, with the formula Ni aZn (1-a)Fe 2O 4). NiZn ferrites exhibit higher resistivity than MnZn, and are therefore more suitable for frequencies above 1 MHz.

Ferrite Core Inductor Software Applications For Computer

For applications below 5 MHz, MnZn ferrites are used; above that, NiZn is the usual choice. The exception is with, where the threshold of choice is at 70 MHz. As any given blend has a trade off of maximum usable frequency, versus a higher mu value, within each of these sub-groups manufacturers produce a wide range materials for different applications blended to give either a high initial (low frequency) inductance, or lower inductance and higher maximum frequency, or for interference suppression ferrites, a very wide frequency range, but often with a very high loss factor (low ). It is important to select the right material for the application, as the correct ferrite for a 100 kHz switching supply (high inductance, low loss, low frequency) is quite different to that for an RF transformer or ferrite rod antenna, (high frequency low loss, but lower inductance), and different again from a ferrite (high loss, broadband) Applications There are two broad applications for ferrite cores which differ in size and frequency of operation: signal transformers, which are of small size and higher frequencies, and power transformers, which are of large size and lower frequencies. Cores can also be classified by shape, such as cores, shell cores or cylindrical cores. The ferrite cores used for power transformers work in the low frequency range (1 to 200 kHz usually) and are fairly large in size, can be toroidal, shell, or shaped like the letters ‘C’, ‘D’, or ‘E’.

They are useful in all kinds of electronic devices – especially power supplies from 1 Watt to 1000 Watts maximum, since more powerful applications are usually out of range of ferritic single core and require grain oriented lamination cores. The ferrite cores used for signals have a range of applications from 1 kHz to many MHz, perhaps as much as 300 MHz, and have found their main application in electronics, such as in and tags. Ferrite rod aerial. Loopstick antenna from an AM radio having two windings, one for and one for (AM broadcast) reception. Typically 10 cm long, these loop antennas are usually hidden inside the radio receiver. Ferrite rod aerials (or antennae) are a type of ( SML) antenna very common in, although they began to be used in ('valve') radios in the 1950s. They are also useful in (VLF) receivers, and can sometimes give good results over most of the shortwave frequencies assuming a suitable ferrite is used).

They consist of a coil of wire wound around a ferrite rod core (usually several inches longer than the coil, but sometimes over 3 feet long ). This core effectively ‘concentrates’ the magnetic field of the radio waves to give a stronger signal than could be obtained by an air core loop antenna of comparable size, although still not as strong as the signal that could be obtained with a good outdoor wire aerial. Other names include, ferrod, and ferrite-rod antenna.

' Ferroceptor' is an older alternative name for a ferrite rod aerial, particularly used by where the ferrite core would be called a ' rod (a brand name acquired by from Philips in the year 2000). The short terms ferrite rod or ‘loop-stick’ sometimes refers to the coil-plus-ferrite combination that takes the place of both an external antenna and the radio’s first tuned circuit, or just the ferrite core itself (the cylindrical rod or flat ferrite slab). See also.

Ferrite Core Inductor Calculator

References.