Archdale Drill Manual Electric

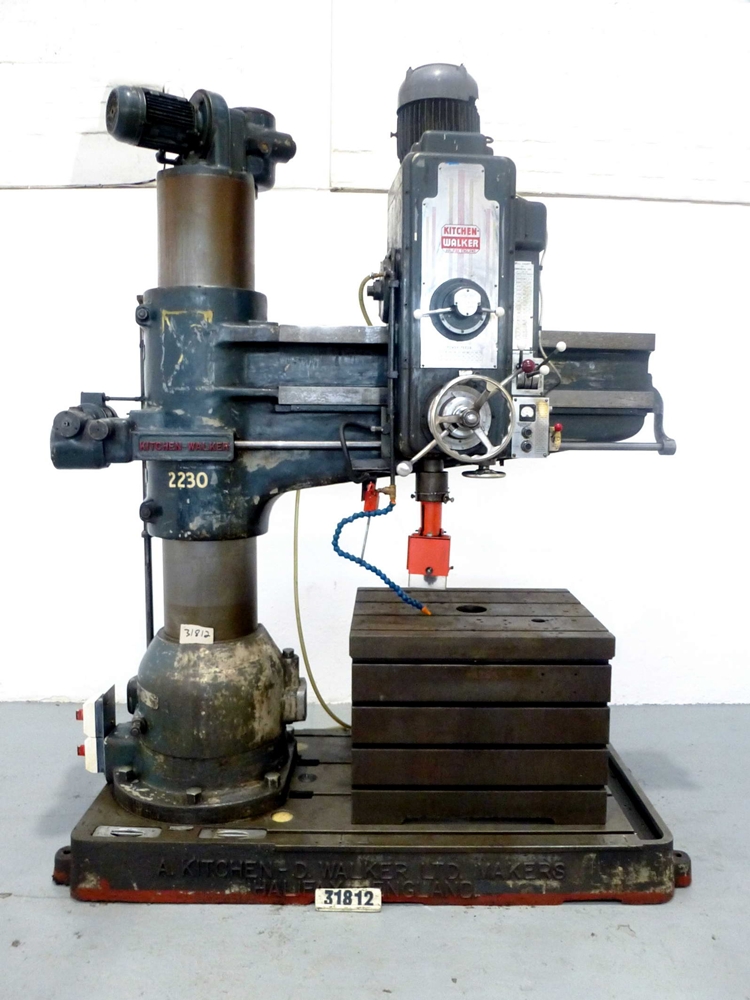

Have been working on an old Archdale radial arm drill. The only?model number I can see is RD 7050 and the drill certainly seems 30-40s era. Have slowly sorted out the various functions and the drill seems to work well. Have decided to drain the oils in the spindle head and the gearing for raising and lowering the arm. Any ideas as to the type of oil to use? Also where is the oil filler point for the spindle gearbox.

There is a circular opening on the top of the spindle head that from old photos had a glass cover.?is that the filler point. Mine has been replaced with a metal replacement. Device seizure 5 keygen. Are?manuals available anywhere?

Thanks for viewing Mark. Hi Mark 123, ' Archdale ' made really good radial arm drills so you've struck lucky there. As I recall that ' tower ' on top of the drilling head should be a sight glass for the pumped oil supply in the drilling head. It should be a large dia clear plastic/glass tube so you can see the oil supply being delivered to the top of the gearbox. You really need to make it clear again. Given their position they're very prone to ' swinging crane hook ' style damage. I've had the same problem and I've milled a flat on both sides of the metal tube and glued a strip of plastic on either side so you can actually see the flow.

The old water tap style knob sticking out of the right hand top of the drilling head is for a ' comb ' style oil filter. The idea is to turn it a few time every day. You need to take it out and clean it.

Archdale Radial Drilling Machine Manual. Installation and maintenance manual.Approximately 22 pages, with information on, installation, lubrication, operating, adjustments, with detailed drawings.

DO NOT take the filter unit itself apart, just clean it in paraffin. Don't ask how I know that!

I think the drilling head oil filler cap is that knurled plug you can see just in front of the tower in one of the photo's. There should be a sight glass lower down on the front of the drilling head for the oil level. I'd use a light to medium gear oil to fill the drilling head. I'm not really as familiar with that era of ' Archdale ' drill as I am with the later pre-op style of drills but there are many similarities.

I'd say your drill was probably made in the early 1950's. I can see the metal strip that should cover the elevating screw is missing but that's not unusual and it isn't the end of the world.

I can't see clearly but are the ' doctor ' strips that protect the ways intact? How are the locks on the arm? They're easy to adjust, as are the roller bearing way guides.

Archdale Drill Manual Electric Bike

Regards Tyrone. Hello,+1 on Mr Shoelaces words-I have it's twin here, ex Ransomes in Ipswich where they made ploughs for 150yrs. Apart from the ammeter giving up it has been trouble free for the last 27yrs.

Mine has a filler pipe beside the level glass next to forward/reverse switch, good for topping up. Don't expect the oil to appear that quickly if drilling 2'+ -it must be driven from well through spindle box as spindle speed is reflected in oil flow.

I had another identical drill a few years ago.it had an exciting day once back in history when the toggle on a rope controlled electric gantry crane caught something in the shop, a chain sling on the crane wrapped itself round the elevating box, slid the old girl downshop and through the brick wall. Another good reason to bolt it down I suppose.not a bad idea anyway if doing any work on the side of the block. Regards, Richard. Keep the slide rail for counterweight clean as if it sticks then drops not so good. Hi mark, I have two Archdale drills, one is very similar to yours, stands about 9/10 foot tall. All I did sofar was rewire it, I still have some things to do but it works when I need it which isn’t often. The forward/reverse lever is missing and the lever handle behind the travel wheel is also missing.

So I ask what is the lever for. I don’t know how to use it really but it does drill when I need it. The other one is smaller, I need to make a gear for it, which has been going on now for about five years. I have just got round to modifying my mill to take the dividing head and of course a couple of the dividing head gears are missing. I recently put up a post about making the gear “ Cutting a helical gear.

1 COPIES OF MACHINE MANUALS For a price ring quoting the file number Visit our website Manufacturer / Make Item / Type Model No & Info File No.